Services

In-Situ Ice Blasting

CORMETECH’s pluggage removal technique for SCR catalyst provides a highly efficient way to reduce pluggage and improve SCR performance. Due to the typically combustion dust laden environment within the SCR, the SCR catalyst can experience mild to severe pluggage, which reduces the nitrogen oxide (NOx) removal efficiency.

CORMETECH’s pluggage removal technique for SCR catalyst provides a highly efficient way to reduce pluggage and improve SCR performance. Due to the typically combustion dust laden environment within the SCR, the SCR catalyst can experience mild to severe pluggage, which reduces the nitrogen oxide (NOx) removal efficiency.

CORMETECH’s Ice Blasting technique provides a unique opportunity of cleaning any SCR catalyst type (corrugated, honeycomb, plate) while being installed within the reactor. This reduces material handling and outage time as well as costs. With CORMETECH’s technique a pluggage reduction from 45-90 percent to less than 5 percent can be achieved.

The utilization of dry ice within the cooled SCR reactor is safe and convenient. The residence time of moisture on the catalyst walls is significantly reduced and therefore the formation of concrete like pluggage is severely minimized compared to other in-situ cleaning techniques.

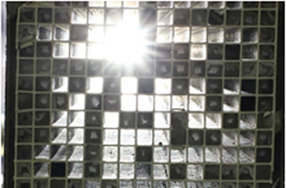

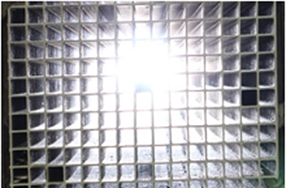

The images above show honeycomb catalyst that had about 65 percent of coal ash dust pluggage before (left) Ice Blasting and afterwards (right) less than 5 percent. The change in light reflection visible shows how significant the improvement for your reactor performance can be.

CORMETECH can customize your SCR catalyst cleaning experience from a one-day demonstration to a full reactor cleaning. Contact us today!

Technology is protected by US Patent Number: 8,268,743