Services

CFD Modeling

Computational fluid dynamics (CFD) is a way of analyzing problems that involve fluid flows. In more complicated terms, the program uses a digitally constructed model of the boiler and solves equations for a set of given inputs related to energy, momentum and chemical composition. All this number-crunching results in a visualization that displays how properties like temperature or NOx production function inside the boiler, enabling CORMETECH engineers to make design adjustments easily.

CORMETECH has used CFD modeling since 1992 to diagnose issues related to high NOx and CO emissions, air flow distribution and fuel utilization. The model has also been employed as a routine step in SNCR design (see image in sidebar) and for determining how effective various other NOx emission control technologies will be. Our experience includes a wide variety of boiler types, including stoker, tangential-fired, cyclone-fired and opposed-fired.

Even supposedly identical boilers rarely function the same, so each CFD profile is unique. CORMETECH's ability to tailor a model to your specific needs means more accurate, predictable results, either with conventional technologies or solutions that are more cutting edge.

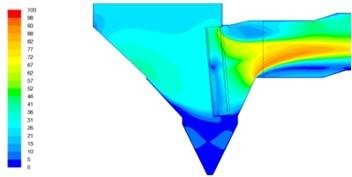

A flow model calculates velocity through an economizer outlet duct fitted with an LPA screen.