Stationary Catalysts

SCR Catalyst

CORMETECH manufactures homogeneous titania-based ceramic honeycomb SCR catalysts for the power generation, industrial, and petrochemical industries worldwide. Our SCR catalysts are used on boilers, turbines, and engines (stationary, marine, and mobile). CORMETECH has the largest installed SCR catalyst base operating in more than 1,500 SCR systems, totaling over 140,000 MW of generating capacity worldwide.

Our unique SCR Catalyst product features include:

Our unique SCR Catalyst product features include:

- High DeNOx removal

- High Mercury Oxidation rate

- Low SO2 --> SO3 conversion rate

- Low pressure drop & ammonia slip

Custom Made SCR Catalysts

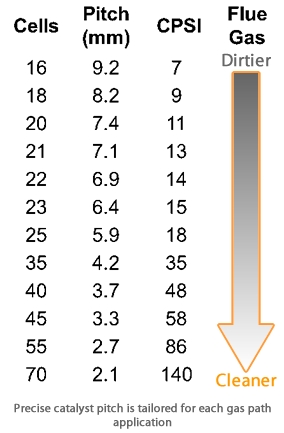

CORMETECH's SCR catalyst formulation and cell pitch are customized for each flue gas application, ensuring high NOx reduction efficiency and high Mercury oxidation rate at very low-pressure loss. Our honeycomb construction offers higher mechanical strength for catalyst durability in addition to an efficient geometry for high surface area and low-pressure drop. We determine the honeycomb structure and cell pitch for each customer application following an engineered analysis of system performance requirements. Our catalysts are installed in carbon steel frames for easy handling during installation and replacement.

Our catalysts are versatile and can be operated over a wide temperature range and provide excellent resistance to sulfur, poisons, and erosion, resulting in long life and low overall cost to the customer.

CORMETECH's SCR Catalyst Solutions

SCR Catalyst Field Services

SCR Catalyst Management

CORMETECH SCR Catalyst Management services will determine an optimum catalyst replacement or addition plan through performance audits designed to determine the remaining potential of the field catalyst

SCR Engineering & Design

By installing an SCR, a coal-fired power plant can significantly reduce the amount of NOx in the flue gas.

SCR Catalyst Regeneration

CORMETECH’s regeneration process removes catalyst deactivation compounds and restores catalyst activity back to the original OEM level

SCR Catalyst Testing

Pilot testing and audits of SCR catalyst activity though laboratory analysis of catalyst samples can provide insight into methods for extending catalyst life.