Services

SCR Catalyst Inspection

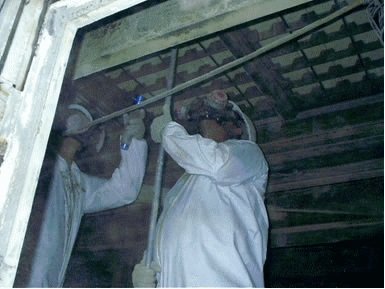

SCR catalyst inspection is essential in planning an effective catalyst management program as each SCR outage represents an opportunity to learn more about operating conditions, resulting in improved performance and reliability, extended lifetime, and reduced O&M costs. CORMETECH offers inspection services by experienced technical personnel who can identify and analyze catalyst performance. Our inspections typically include the following steps:

SCR catalyst inspection is essential in planning an effective catalyst management program as each SCR outage represents an opportunity to learn more about operating conditions, resulting in improved performance and reliability, extended lifetime, and reduced O&M costs. CORMETECH offers inspection services by experienced technical personnel who can identify and analyze catalyst performance. Our inspections typically include the following steps:

- Visual inspection (reactor, catalyst, ammonia injection grid) and SCR catalyst sampling

- Maintenance of expansion joints and catalyst seals

- SCR catalyst activity testing in our bench scale reactor

- SO2/SO3 conversion rate testing in our bench scale reactor

- Catalyst pressure drop measuring in our bench scale reactor

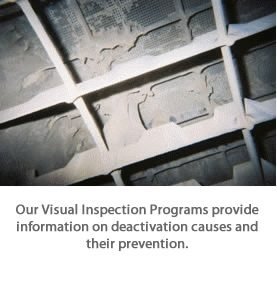

- Determination of the main deactivation causes

- Determination of opportunities (and limitations) for catalyst refurbishment

- Documentation of deactivation causes and activity tracking

- Development of catalyst management strategies

SCR system inspections and evaluations should be performed at least once a year and should include physical inspections of the catalyst, reactor, and ammonia injection grid system. Our visual inspection programs provide information on deactivation causes and their prevention, which is key to extending the life of the catalyst. Our inspection programs include schedules for testing, catalyst cleaning, catalyst restoration, and catalyst replacement strategy.

SCR Catalyst Sample Retrieval